- Shangxian West Road, Xinsanban Industrial Park, Pingxiang Economic And Technological Development Zone, Pingxiang City, Jiangxi Province, China

- export@xt988.com

- +86-799-6611966

Trace water is an important issue in the production and preparation of polyurethane (PU) products. Trace water in polyol reacts with isocyanate to generate carbon dioxide and produce foaming. At the same time, a large amount of heat is released, resulting in a shortened service life.

Activated Molecular Sieve Powder as an additives added to polyurethane , mainly to remove water and dehydrate, and can also smooth the surface, eliminate bubbles, extend service life, improve material uniformity, absorb exhaust gas, and remove odor.

3A Activated Molecular Sieve Powder is made by adding special additives to molecular sieve synthetic powder and calcining it at high temperature. Since the molecular sieve powder loses most of its water content during the high-temperature calcination process, the powdered molecular sieve has strong activity and can be directly used in production as an adsorbent with selective adsorption. It can be mixed with materials for dispersed adsorption and adsorb impurities such as water that affect product quality without changing the physical and chemical properties of the product itself.

Xintao 3a Activated Molecular Sieve Powder is widely used in the production process of polyurethane adhesives, sealants, elastomers, coatings, paints, rubber and other products. Adding a trace amount of powder can significantly improve the stability, durability, hardness, elasticity, etc. of polyurethane products. At the same time, the use of molecular sieve dehydrating agent can also shorten the dehydration time for polyurethane manufacturers and reduce production costs. It is an indispensable win-win product.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Xintao's Activated Molecular Sieve Powder production adopts an integrated automated production line, which ensures temperature and water control throughout the process from powder mixing, firing, cooling, packaging, and storage.

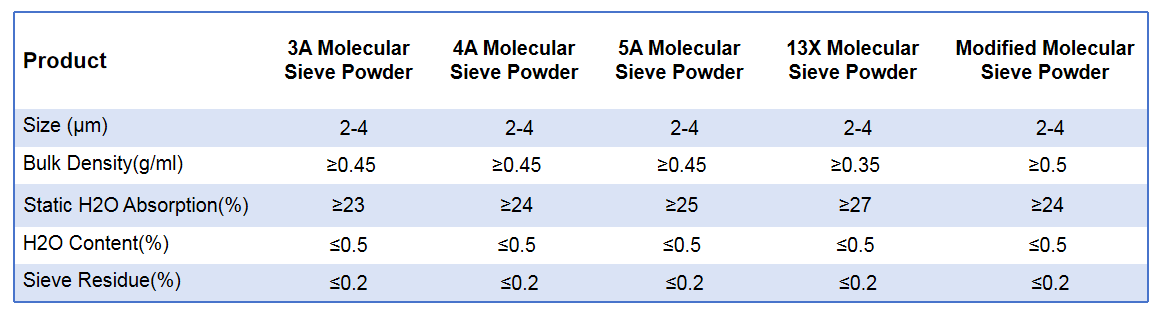

Xintao's Activated Molecular Sieve Powder has a particle size of 2-4 microns, and the powder uniformity and precision are better than the industry level. After mixing, it can easily pass through the high-density screen without clogging, forming particles or agglomerations.

Tests have shown that the AMSP Type 3A can absorb ≥23% of its own weight of water, and it is not easy to release, and has good storage stability

Xintao has many export and customer service cases, you can learn about them here.

During the production of two-component polyurethane, bubbles are often generated due to the influence of moisture, which affects the product quality. The activated molecular sieve powder produced by Xintao has become a new choice

During the glue production and pouring process, the problem of colloid bubbles is often encountered. The bubbles in the colloid will affect the bonding effect between the glues, resulting in a shortened service life and even colloid separation. How do you solve this problem?

The performance of potting compound will be affected by moisture, including the moisture content of the potting compound itself and its ability to isolate moisture after sealing. Adding activated powdered molecular sieve can effectively solve the problem.

Activated Molecular Sieve Powder uses internal channels for physical adsorption to absorb excess water in the polyurethane system to block the isocyanate reaction. At the same time, Xintao 5A and 13X activated molecular sieve powders can also directly adsorb carbon dioxide gas to play a defoaming role.

The principle of defoamer is to break the balance of foam stability. The defoamer penetrates into the colloidal foam thin layer and forms a monomolecular film, which reduces its adhesion and makes it easy for the thin layer to break, thereby breaking the pores.

Activated powder does not increase viscosity. It is purely physically adsorbed. The addition ratio is low, and it can enhance the bonding strength to a certain extent.

Component A of two-component polyurethane is generally polyester polyol and polyether polyol, and activation powder is generally added to component A.

If you have any question, contact us!

We will contact you by email within 24 hours, please check your email inbox in time.

Strict Quality Control

Xintao has always insisted on quality first, and we will provide you with products that meet international high standards.

Complete Production Line

Xintao Factory is equipped with a series of industry-leading production equipment, with 10 fully automatic integrated production lines.

Professional Service

We adhere to the service concept of customer first. We will provide you with 24-hour free consultation, full-process technical support for products and free sample delivery services, etc.