- Shangxian West Road, Xinsanban Industrial Park, Pingxiang Economic And Technological Development Zone, Pingxiang City, Jiangxi Province, China

- export@xt988.com

- +86-799-6611966

Activated Molecular Sieve Powder is a synthetic powder molecular sieve that has been dehydrated. Since the molecular sieve itself has nano-scale pores, the water inside the pores is removed and lost during the high-temperature roasting process, so the finished product has strong activity.

Xintao activated molecular sieve powder, as an active powder of micron size, has the characteristics of strong water absorption, good dispersibility, and fast adsorption speed. It is used in some special adsorption occasions, such as as a mixed raw material in the production process of polyurethane, mixed with isocyanate components to absorb water and impurities such as carbon dioxide. It can be used as an additive or base material in polyurethane adhesives, sealants, polymers, coatings, resins and rubbers.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

3A activated molecular sieve powder is a potassium-type zeolite with an A-type crystal structure, which enables it to selectively adsorb molecules according to molecular size and polarity. Type 3A Powder can adsorb all molecules with an effective diameter of less than 3 angstroms, such as water molecules.

Adding a certain amount of activated molecular sieve powder to the system can remove the residual moisture in the PU system, but it will not adsorb macromolecular materials, nor change the chemical properties of the product, and play a role in avoiding the formation of bubbles and extending the service life of the material. Therefore, activated molecular sieve powder is an excellent additive powder dehumidifier for polyurethane plastic runways, sealing glue, paints, coatings, epoxy resin floor paints, AB glue and sealants.

4A activated molecular sieve powder is a sodium-based zeolite dehydration desiccant powder based on A-type crystal structure, with good selective physical adsorption performance.

Type 4A Powder can adsorb all molecules with an effective diameter of less than 4 angstroms, In the polyurethane system, activated 4a molecular sieve powder is used as a powder form additive and mixed in polyurethane coatings, paints, resins, adhesives and sealants.

Adding activated powder into the reactor and stirring the raw materials can absorb water and CO2, effectively reduce the generation of bubbles, improve the uniformity and strength of the material, form a smooth product surface, and enhance the strength of coatings and adhesives.

5A Activated Molecular Sieve Powder is a calcium (Ca) type molecular sieve adsorbent with a pore size of 5 angstroms with A type crystal structure. It has excellent dispersibility, adsorption activity and chemical stability, and is particularly suitable for selective adsorption of small molecules and polar molecules. It is used to adsorb trace amounts of moisture, carbon dioxide, hydrogen sulfide, and other waste gas impurities generated during the production process.

Type 5A Powder as an additive, it is widely used in products such as polyurethane coatings, paints, rubber, adhesives, sealants and plastics.

13X activated molecular sieve powder is a sodium-type X-type zeolite ultrafine powder. Its particle size is much larger than that of the A-type crystal structure. The adsorption pore size is 10 angstroms, and it can adsorb molecules below 1nm.

Type 13X Powder often used as an amorphous adsorbent with selective adsorption performance in the production of polyurethane adhesives, sealants and coatings. It can effectively remove trace amounts of moisture, hydrogen sulfide, carbon dioxide and other gases in the material, play a role in dehydration, eliminate bubbles, remove odors, prolong the use of materials.

Modified molecular sieve powder, also known as polyurethane dehydration and defoaming molecular sieve, is a patented product independently developed by Xintao. It can help adjust the pH of polyurethane glue, and the static water adsorption is greater than or equal to 24%. It is specifically used to remove unnecessary reaction water in the polyurethane system.

Xintao provides a variety of activated molecular sieve powders to solve the water content and bubble problems in your adhesives. Overseas customers often choose to use 3A molecular sieves for dehydration applications

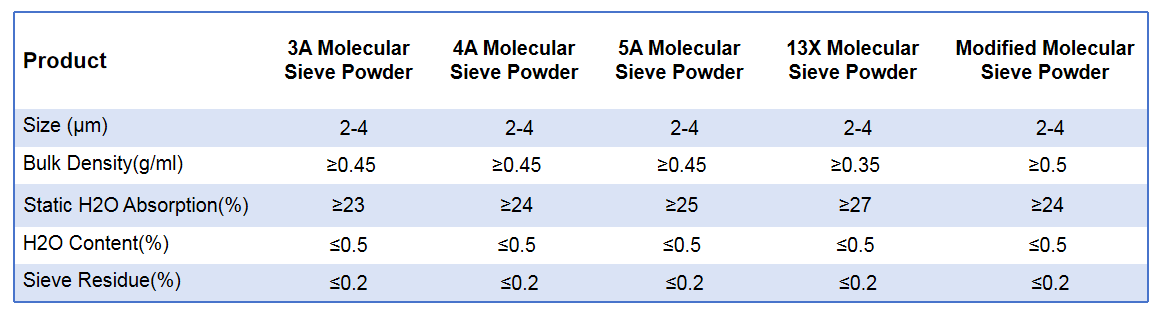

Other manufacturers often have black particles or agglomerates in their powders due to problems with raw materials, production equipment, and processes. However, Xintao activated molecular sieve powder guarantees a powder fineness of 2-4 microns, and uses high-quality raw materials to ensure uniform color without impurities.

Xintao provides customers with free samples for product testing and R&D testing, and guarantees full technical services with rich industry experience.

Xintao has many export and customer service cases, you can learn about them here.

During the production of two-component polyurethane, bubbles are often generated due to the influence of moisture, which affects the product quality. The activated molecular sieve powder produced by Xintao has become a new choice

During the glue production and pouring process, the problem of colloid bubbles is often encountered. The bubbles in the colloid will affect the bonding effect between the glues, resulting in a shortened service life and even colloid separation. How do you solve this problem?

The performance of potting compound will be affected by moisture, including the moisture content of the potting compound itself and its ability to isolate moisture after sealing. Adding activated powder molecular sieve can effectively solve the problem.

It can be used for any product where trace moisture in the glue will affect the properties of the product. If you use traditional dehydration equipment, the entire dehydration process takes a long time. You can also choose activated molecular sieve powder to speed up the dehydration process.

The difference is that molecular sieve powder is the single raw material for producing molecular sieves, which has low activity and cannot absorb water. Activated molecular sieve powder is a powder with adsorption activity produced by adding specific additives and dehydrating at high temperature.

Usually, the addition ratio is 2-6%. The amount of activated molecular sieve powder to be added is determined according to the trace amount of water that needs to be removed in the system. The static water adsorption is ≥24%, which means that under certain conditions, the amount of water that the activated powder can absorb is 24% of its own weight.

No. Activated powder is also a kind of molecular sieve, which belongs to static molecular sieve and cannot be regenerated in the system. The adsorption and desorption of molecular sieves are conditional. Desorption requires high temperature and low pressure. When used by customers, the molecular sieve activated powder forms a uniform substance with polyurethane and does not have the desorption conditions. This is also the reason why the activated powder cannot be regenerated.

If you have any question, contact us!

We will contact you by email within 24 hours, please check your email inbox in time.

Strict Quality Control

Xintao has always insisted on quality first, and we will provide you with products that meet international high standards.

Complete Production Line

Xintao Factory is equipped with a series of industry-leading production equipment, with 10 fully automatic integrated production lines.

Professional Service

We adhere to the service concept of customer first. We will provide you with 24-hour free consultation, full-process technical support for products and free sample delivery services, etc.