Molecular Sieve Manufacturer

20+ Years Global Leading Brand

There is chemical industry, there is Xintao chemical packing

Carbon Molecular Sieve

Carbon molecular sieve, the main component is elemental carbon, and its appearance is a black columnar solid. Because it contains a large number of micropores, these micropores allow molecules smaller than its pore size to enter quickly, and restrict the entry of molecules larger than the pore size. For example, when separating nitrogen and oxygen, the micropores have a strong instantaneous affinity for oxygen molecules. Oxygen can quickly diffuse into the pores through the pores, while nitrogen is difficult to pass through. Therefore, it can be used to separate nitrogen and oxygen in the air. Xintao carbon molecular sieve is suitable for various types of pressure swing adsorption nitrogen generators.

Product Detail

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Why Choose Xintao Carbon Molecular Sieve

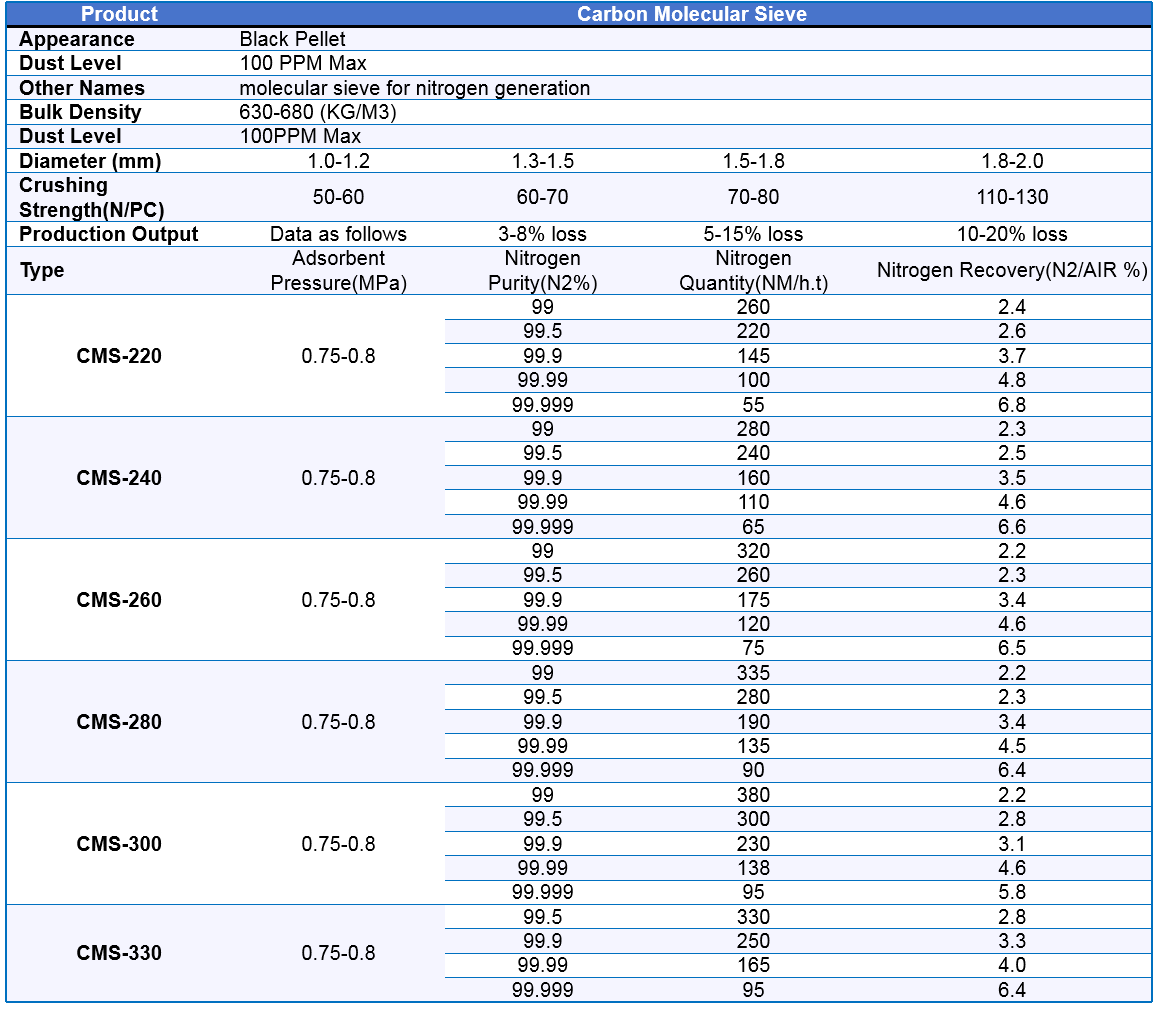

Xintao carbon molecular sieves have a wide variety of types for you to choose. Such as CMS -220, CMS-240, CMS-260, CMS-280, CMS-300, CMS-330.

- High adsorption efficiency

- High strength

- Stable chemical properties

- High nitrogen recovery rate

- Long service life

- High temperature resistance, acid and alkali resistance

- High nitrogen purity (N2 purity up to 99.999% at 0.75~0.8 MPa)

Technical Parameter

Carbon Molecular Sieve Applications

Xintao Carbon molecular sieves have unique adsorption and separation effects, we provides high-quality, high-nitrogen-yielding CMS that are widely used in many fields.

Gas Separation

Providing high-purity nitrogen for chemical, metallurgical, electronic, pharmaceutical and environmental protection industries.

PSA Nitrogen Generation

Using cms selective adsorption of nitrogen and oxygen in the air to produce high-purity nitrogen.

Oil Refining

In the oil refining process, carbon molecular sieve is used for hydrogen purification and desulfurization

Food Preservation

Absorbing ethylene gas produced by fruits and vegetables to delay their ripening process.

Electronic Gas Purification

Removing impurities and moisture from the gas during the manufacturing process of electronic chips.

our successful cases

Cases of Carbon Molecular Sieves in Nitrogen Generator

The main function of Xintao carbon molecular sieves is to produce nitrogen and can be widely used in various industries.

Xintao Exported 33 Tons of Carbon Molecular Sieve to Europe

The customer needs carbon molecular sieve that used in PSA nitrogen generator, Xintao carbon molecular sieve can produce high purity nitrogen, which meets his needs well.

More Than 10 Tons of Carbon Molecular Sieve Exported to Europe

As a carbon molecular sieve manufacturer, we are extremely efficient. It takes less than two weeks from confirming the order to completing the production of more than ten tons of carbon molecular sieve. The packaging and shipment are then completed immediately. The compact process ensures that the shipment is in time.

Xintao Carbon Molecular Sieve Nitrogen Generator Filling Guidance

Xintao provides carbon molecular sieve installation guidance for a cooperative customer, and the final test nitrogen concentration is as high as 99.99%.

FAQ

Carbon molecular sieve adsorbs oxygen gas, carbon dioxide gas, moisture and so on in compressed air in a short period of time and compressed nitrogen gas is available at the outlet. When the pressure decreases to the atmospheric or vacuum level, CMS which has adsorbed oxygen gas and others easily desorbs them and is regenerated.

Xintao provide CMS220, CMS240,CMS260, CMS280, CMS300, CMS 330.

There are different diameters to choose from 0.95-1.1mm, 1.1-1.3mm, 1.3-1.5mm to 1.5-1.8mm etc.Xintao Carbon Molecular Sieve, has the character of large N2 yield capacity and high N2 recovery. It has long service life, is suitable for various types of PSA nitrogen making machine.

The service life of Xintao carbon molecular sieve is usually 5 years, but it is affected by the quality of raw gas, working environment, frequency of use and regeneration. For example, carbon molecular sieve can maintain good adsorption performance within the normal working temperature range. Too high temperature will intensify the molecular movement, causing the adsorbed gas molecules to desorb easily, and it may also change the structure of the CMS, affecting its service life.

Video Introduction

Related Products

Get A Free Quote

If you have any question, contact us!

We will contact you by email within 24 hours, please check your email inbox in time.

Benefit You Get

Strict Quality Control

Xintao has always insisted on quality first, and we will provide you with products that meet international high standards.

Complete Production Line

Xintao Factory is equipped with a series of industry-leading production equipment, with 10 fully automatic integrated production lines.

Professional Service

We adhere to the service concept of customer first. We will provide you with 24-hour free consultation, full-process technical support for products and free sample delivery services, etc.

Get A Free Quote

We will contact you by email within 24 hours, please check your email inbox in time.