As a carbon molecular sieve suppliers, Xintao will introduce you to CMS from its introduction to its working principle to PSA nitrogen production technical indicators, specific requirements, conditions to be controlled and industrial applications.

Table of Contents

ToggleXintao's Carbon Molecular Sieve Introduction

As a carbon molecular sieve suppliers, the main component of xintao carbon molecular sieve is elemental carbon, and its appearance is black columnar solid. Because it contains a large number of micro-pores with a diameter of 4 angstrom, the micro-pores have strong instantaneous affinity for oxygen molecules and can be used to separate oxygen and nitrogen in the air.

It usually is used to separate air and enrich nitrogen. It adopts normal temperature and low pressure nitrogen production process. Compared with the traditional cryogenic high pressure nitrogen production process, it has the advantages of less investment cost, fast nitrogen production speed and low nitrogen cost. Therefore, it is the preferred pressure swing adsorption (p.s.a) nitrogen rich adsorbent for air separation in the engineering industry.

Nitrogen is produced by pressure swing adsorption device (PSA) in industry. Carbon molecular sieve has large nitrogen production capacity, high nitrogen recovery rate and long service life. It is suitable for various types of pressure swing adsorption nitrogen generator.

This nitrogen produced by xintao’s carbon molecular sieve is widely used in chemical industry, oil and gas industry, electronic industry, food industry, coal industry, pharmaceutical industry, cable industry, metal heat treatment, transportation and storage.

Working Principle of Carbon Molecular Sieve

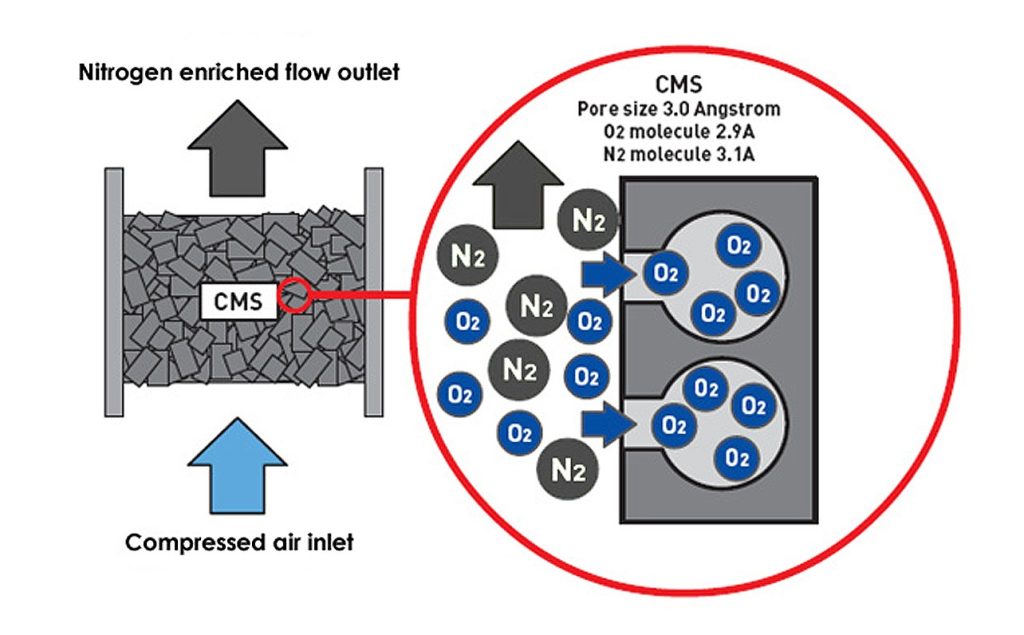

Carbon molecular sieve uses the characteristics of screening to separate oxygen and nitrogen. When molecular sieves adsorb impurity gases, macropores and mesopores only play the role of channels, transporting the adsorbed molecules to micropores and sub micropores, and micropores and sub micropores are the volumes that really play the role of adsorption.

As shown in the previous figure, there are a large number of micropores in the carbon molecular sieve, which allow the molecules with small kinetic size to quickly diffuse into the pores while limiting the entry of large-diameter molecules. Due to the difference of relative diffusion rate of gas molecules with different sizes, the components of gas mixture can be effectively separated.

Therefore, when manufacturing carbon molecular sieve, according to the molecular size, the micropore distribution in carbon molecular sieve will be controled in 0.28 ~ 0.38nm. Within the micropore size range, oxygen can quickly diffuse into the micropore through the micropore orifice, while nitrogen is difficult to pass through the micropore orifice, so as to achieve the separation of oxygen and nitrogen. The pore size of micropores is the basis for the separation of oxygen and nitrogen by carbon molecular sieves. If the pore size is too large, oxygen and nitrogen molecular sieves can easily enter the micropores and can not play the role of separation; The pore size is too small, oxygen and nitrogen can not enter the micropores, and can not play the role of separation.

Carbon Molecular Sieve for PSA Nitrogen Generators

Nitrogen generator refers to the equipment that takes air as raw material and uses physical adsorption methods to separate oxygen and nitrogen to obtain nitrogen. This article will focus on the carbon molecular sieve pressure swing adsorption (PSA)

Nitrogen Generation By Carbon Molecular Sieve In Nitrogen Generator

Taking air as raw material and cms carbon molecular sieve as adsorbent, separating nitrogen and oxygen by using the principle of and the selective adsorption of carbon molecular sieve, generally known as PSA nitrogen production.

It has the characteristics of simple process flow, high degree of automation, fast gas production, low energy consumption, product purity can be adjusted in a large range according to the needs, convenient operation and maintenance, low operation cost and strong adaptability of the device. PSA nitrogen production has become a preferred method for nitrogen generators vender.

Technical indicators:

Flow: 5-1000nm3 / h

Purity: 95% – 99.9995%

Dew point: ≤ – 40 ℃

Pressure: ≤ 0.85MPa adjustable

PSA nitrogen equipment specific:

(1) Convenient and fast nitrogen production:

Advanced technology and unique air distributor make the air distribution more uniform. Carbon molecular sieve can be used efficiently to provide qualified nitrogen in about 20 minutes.

(2) Easy to use:

The equipment is compact in structure, skid mounted as a whole, occupies a small area, does not need capital construction investment, and has less investment. Nitrogen can be produced only by connecting power supply on site.

(3) More economical than other nitrogen supply methods:

PSA process is a simple nitrogen production method, which takes air as raw material and consumes only the electric energy consumed by the air compressor. It has the advantages of low operation cost, low energy consumption and high efficiency.

Conditions To Be Controlled For Nitrogen Production From Carbon Molecular Sieve

Air compression purification process

It is very necessary for pure feed air to enter the carbon molecular sieve adsorption tower, because the entry of particles and organic atmosphere into the adsorption tower will block the micropores of carbon molecular sieve and gradually reduce the separation performance of carbon molecular sieve.

The methods of purifying raw air are as follows: 1. Keep the air inlet of the air compressor away from places with dust, oil mist and organic atmosphere; 2. Through the cold dryer and adsorbent purification system, the treated raw air enters the carbon molecular sieve adsorption tower.

Concentration and gas production of product nitrogen

For the preparation of nitrogen from carbon molecular sieve, the N2 concentration and gas production can be adjusted arbitrarily according to the needs of users. When the gas production time and operating pressure are determined, reduce the gas production, the N2 concentration will increase, on the contrary, the N2 concentration will decrease. Users can adjust according to actual needs.

Equalizing time

When the pressure of the adsorbed gas in the two molecular sieves reaches the same direction, the service life of the adsorbed gas can be prolonged by injecting the adsorbed gas into the two molecular sieves in the same direction, so as to prolong the service life of the two molecular sieves. Referring to the switching speed of the valve, the voltage equalizing time is generally 1 ~ 3 seconds.

Gas production time

According to the different absorption and diffusion rates of carbon molecular sieve for oxygen and nitrogen, its adsorbed O2 will reach equilibrium in a short time. At this time, the adsorption capacity of N2 is very small, and the shorter gas production time can effectively improve the gas production rate of carbon molecular sieve, but it also increases the action frequency of the valve, so the performance of the valve is also very important. Generally, the adsorption time is 30 ~ 120 seconds. Short gas production time is recommended for small-scale high-purity nitrogen generator, and long gas production time is recommended for large-scale low concentration nitrogen generator.

Operating pressure

Carbon molecular sieve not only has dynamic effect, but also has equilibrium adsorption effect. The partial pressure of adsorbate is high and the adsorption capacity is high. Therefore, pressurized adsorption is beneficial, but the adsorption pressure is too high, which also increases the requirements for the selection of air compressor. In addition, the adsorption pressure requirements of atmospheric regeneration and vacuum regeneration are also different. Considering various factors, it is suggested that the adsorption pressure of atmospheric regeneration process should be 5 ~ 8kg / cm2; The adsorption pressure of vacuum regeneration process should be 3 ~ 5kg / cm2.

Service temperature

As an adsorbent, choosing a lower adsorption temperature is conducive to the performance of carbon molecular sieve. If conditions permit, it is beneficial to reduce the adsorption temperature.

Packaging and use of products

1) This product is strictly tested according to the enterprise standard when leaving the factory to ensure that the quality index is qualified.

2) The products are sealed and packaged in plastic barrels with good sealing performance. They can be opened when filling and use to prevent moisture absorption.

3) The filling must be tight and can be vibrated by appropriate methods. Do not tamp it directly with the rod head.

0.1MPa lower than N2 pressure of feed gas

Temperature: ≤ 40 ℃

Industrial Application of Nitrogen Molecular Sieve

As a carbon molecular sieve suppliers, Xintao CMS (carbon molecular sieve) for PSA nitrogen generator have type:

CMS-220 (Carbon molecular sieve 220)

CMS-240 (Carbon molecular sieve 240)

CMS-260 (Carbon molecular sieve 260)

CMS-280 (Carbon molecular sieve 280)

CMS-330 (Carbon molecular sieve 330)

Nitrogen purity reach to: 99.5%-99.9999%.

The special nitrogen generator for oil and gas industry is suitable for nitrogen protection, transportation, coverage, replacement, rescue, maintenance, nitrogen injection and oil production in continental oil and gas exploitation, coastal and deep-sea oil and gas exploitation. It has the characteristics of high safety, strong adaptability and continuous production.

Special nitrogen generator for chemical industry is applicable to petrochemical industry, coal chemical industry, salt chemical industry, natural gas chemical industry, fine chemical industry, new materials and their derivative chemical product processing industry. Nitrogen is mainly used in covering, purging, replacement, cleaning, pressure transmission, chemical reaction stirring, chemical fiber production protection, nitrogen filling protection and other fields.

Special nitrogen making machine for metallurgical industry is suitable for heat treatment, bright annealing, protective heating, powder metallurgy, copper and aluminum processing, magnetic material sintering, precious metal processing, bearing production and other fields. It has the characteristics of high purity, continuous production, and some processes require nitrogen to contain a certain amount of hydrogen to increase brightness.

The special nitrogen generator for coal mining industry is applicable to the fields of fire prevention and fire extinguishing, gas and gas dilution in coal mining. It has three specifications: ground fixed type, ground mobile type and underground mobile type, which can fully meet the nitrogen demand under different working conditions.

The special nitrogen generator for rubber tire industry is suitable for nitrogen protection, molding and other fields in the production and vulcanization of rubber and tires. Especially in the production of all steel radial tire, the new process of nitrogen vulcanization has gradually replaced the steam vulcanization process. It has the characteristics of high nitrogen purity, continuous production and high nitrogen pressure.

The special nitrogen generator for the food industry is suitable for green storage of grain, nitrogen filled packaging of food, preservation of vegetables, sealing (Canning) and preservation of wine, etc.

The special nitrogen generator for pharmaceutical industry is mainly used in drug production, storage, packaging, packaging and other fields.

The special nitrogen generator for the electronic industry is suitable for semiconductor production and packaging, electronic component production, led, LCD, lithium battery production and other fields. The nitrogen generator has the characteristics of high purity, small volume, low noise and low energy consumption.