- Shangxian West Road, Xinsanban Industrial Park, Pingxiang Economic And Technological Development Zone, Pingxiang City, Jiangxi Province, China

- export@xt988.com

- +86-799-6611966

Crude oil is the raw material for producing mineral diesel, and organic sulfur is a natural component of crude oil. If the sulfur in diesel is not treated, it will have many negative effects. When burned, sulfur-containing fuels produce sulfur dioxide (SO2), which can cause acid rain. In addition, sulfur can damage vehicle emission-control systems, such as catalytic converters that remove carbon monoxide (CO), nitrogen oxides (NOx) and hydrocarbons, and the exhaust gas can also have unhealthy effects on the human respiratory system, so oil refineries will perform a certain degree of desulfurization.

Xintao’s sulfur recovery catalyst, innovative application in the desulfurization process, has made breakthrough progress in the desulfurization process. The catalyst is generally a general desulfurization catalyst, cobalt molybdenum catalyst (Co-Mo Catalyst), titanium dioxide catalyst (Tio2 catalyst) or nickel molybdenum catalyst (NiMoCo).

Hydrodesulfurization

Hydrodesulfurization is carried out in a fixed bed reactor, which contains an alumina carrier and a molybdenum-based catalyst, usually cobalt molybdenum (CoMo) or nickel molybdenum (NiMo) catalyst. The catalyst will accelerate the reaction of organic sulfur and hydrogen in hydrocarbon feedstock, reduce the energy required for the reaction process, and make the desulfurization more thorough.

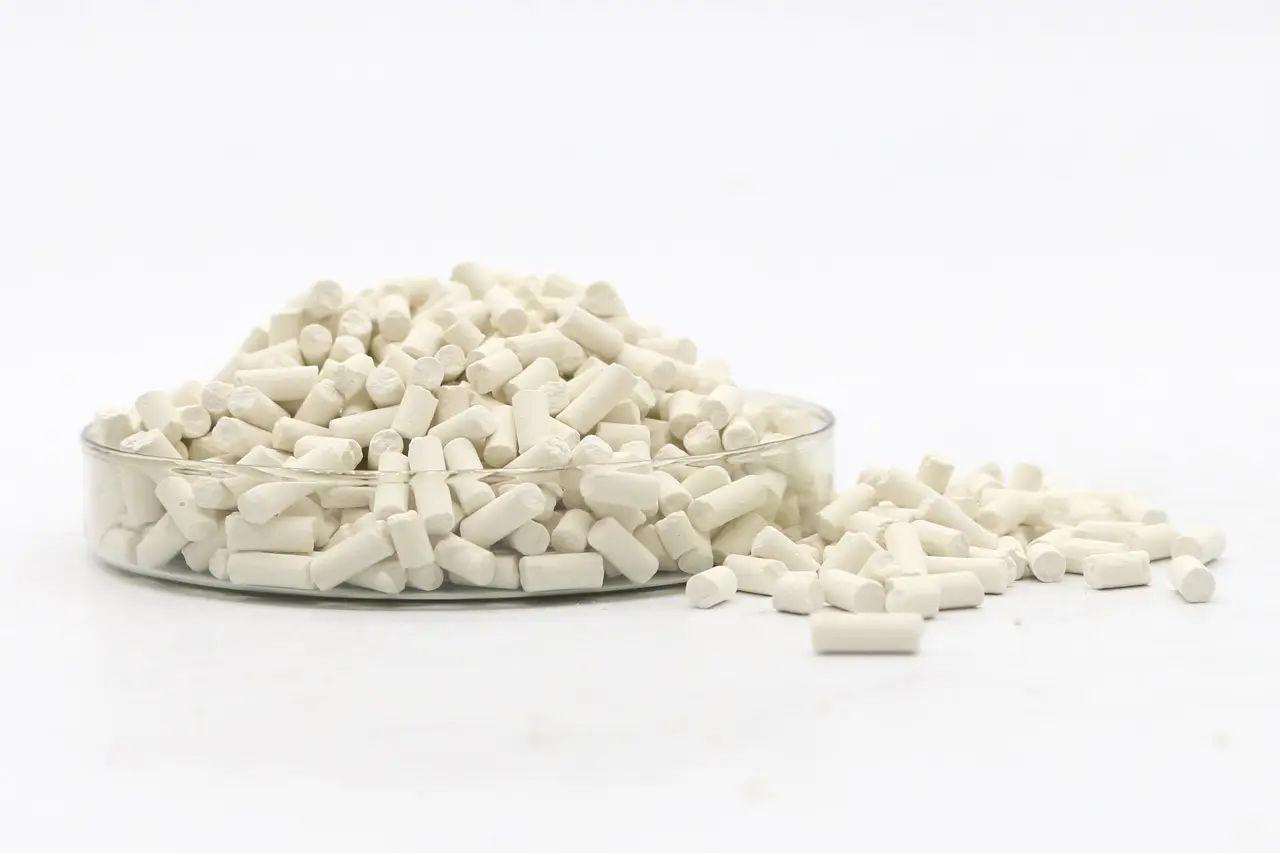

Sulfur Recovery Catalyst

Sulfur recovery is an important process for natural gas processing plants and refineries. Sulfur recovery in the horizontal reactor in the refinery and coal chemical plant uses the Claus process, Claus + Scott process, or Super Claus process. The catalysts used during the process are Xintao’s aluminum-based sulfur-making catalyst, titanium-based sulfur-making catalyst, and iron oxide leakage catalyst.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Alumina (Al2O3) is a porous material with a large specific surface area and high adsorption capacity. It is an amphoteric metal oxide with abundant alkaline sites on the surface and has certain catalytic activity for COS hydrolysis.

XINTAO activated alumina catalyst carrier mainly uses the large pore volume structure and specific surface area of the active alumina ball to absorb the required catalyst solution into the pore volume structure of the active alumina ball, so that the activated alumina ball after special process impregnation has the same function as the catalyst solution.

Zinc Oxide Desulfurization Adsorbent, which is applicable to desulfurization of residue cracking gases or syngas and purification of feed gases for organic synthesis processes. It is suitable for both higher (350–408℃) and lower(150–210℃) temperature use. It can convert some simpler organic sulfur while absorbing inorganic sulfur in gas stream.

Main reaction of the desulfurization process is as follows:

(1) Reaction of zinc oxide with hydrogen sulfide

(2) Reaction of zinc oxide with some simpler sulfur compounds in two possible ways:

a. Organic sulfur compounds, catalyzed by zinc oxide, react with hydrogen to form hydrogen sulfide, then hydrogen sulfide is absorbed by zinc oxide

b. Zinc oxide reacts directly with organic sulfur compounds

XINTAO ZnO Catalyst is an ideal desulfurization adsorbent for deep purification cases, especially those at higher temperature (350–400℃).

Co Mo hydro-desulfurization catalyst is a kind of newly modified hydrodesulfurization catalyst with γ-alumina as the carrier and co&mo as its active components. The catalyst has the characteristics of small bulk density but larger specific tolerance and surface area. The catalyst can be used in the hydrofining process to prepare ammonia synthetic gases, hydrogen and methanol synthetic gases from gaseous hydrocarbons, The catalyst can also be used in the hydrofining process of light naphtha hydrodesulfurization and the reforming feedstock of the refineries.

Cobalt molybdenum hydroconversion desulfurization catalyst (CoMo Catalyst) is suitable for fine desulfurization of various hydrocarbons and gases in fertilizer plants, methanol plants, refinery hydrogen production units, and ammonia desulfurization units that use natural gas, oil field gas, refinery gas and light oil as raw materials. and other raw materials to remove organic sulfur.

TiO2 Based Sulfur Recovery Catalyst is a new kind of TiO2 based catalyst with special additives for sulfur recovery. Its comprehensive performances and technical indexes have reached world advanced level, and it’s in the leading position in domestic industry.

Xintao is a catalyst manufacturer with more than 20 years of experience and has outstanding expertise in developing a wide range of chemicals, adsorbents, catalysts and other products. We provide customers with the broadest range of Claus catalysts, mature technologies and reliable services to meet your expectations and requirements.

Applicable to Claus sulfur recovery units in petrochemical and coal chemical industries, and also to sulfur recovery in catalytic oxidation processes. It can be fully loaded in any reactor, or used in combination with other catalysts of different types or functions. It can increase the hydrolysis rate of organic sulfur in the primary reactor, and increase the conversion rate of total sulfur in the secondary and tertiary reactors.

Xintao's catalyst uses our own special carrier, which has the characteristics of light bulk density, large pore volume and specific surface area, uniform distribution of active components, high hydrogenation activity and organic sulfur hydrolysis activity, and good activity stability. The comprehensive performance and technical indicators of Xintao's catalyst have reached the international advanced level, and it is in a leading position in domestic technology.

The catalyst carrier is a unique application of activated alumina, and its active ingredient functions as a dispersant, adsorbent, and carrier, and can also play the role of co-catalyst or co-catalyst at a certain time.

The catalyst produced by xintao has high strength and high activity. The catalyst can catalyze the conversion of the distillate oil, wax oil, used oil, coal tar and illegal cooking oil.

Activated Alumina Claus catalyst is a high surface area activated alumina sphere. The catalyst is mainly used to catalyze the reaction of H2S and SO2 to produce elemental sulfur in Claus sulfur recovery process.

If you have any question, contact us!

We will contact you by email within 24 hours, please check your email inbox in time.

Strict Quality Control

Xintao has always insisted on quality first, and we will provide you with products that meet international high standards.

Complete Production Line

Xintao Factory is equipped with a series of industry-leading production equipment, with 10 fully automatic integrated production lines.

Professional Service

We adhere to the service concept of customer first. We will provide you with 24-hour free consultation, full-process technical support for products and free sample delivery services, etc.